ELF Science & Technology (Beijing) Co., Ltd

Add:2-2, Floor 1, Building 12, Changan Community, Miyun District, Beijing

Tel:+86 15010117905

Quote Now

Solutions for Your Industry, Ready for Your Choice

Product introduction

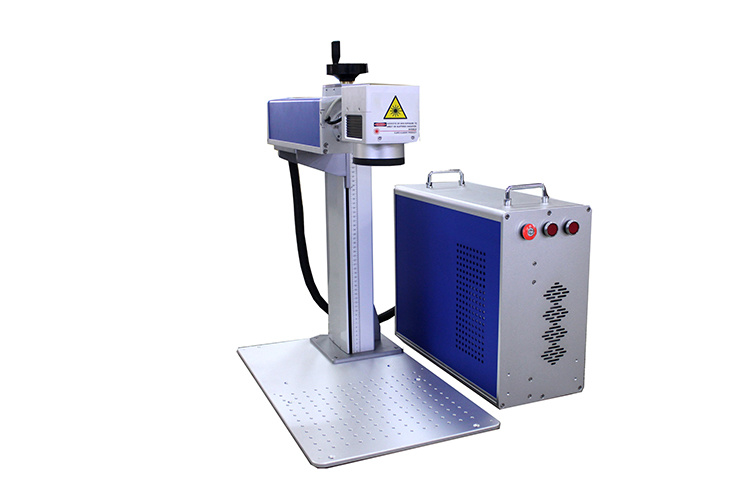

A laser cutting machine cuts materials by using laser beam, which instantly vaporized at high temperature and assisted by air pressure. At the same time, according to the needs calculate and control the motor to move along the track of the graphic content, thereby removing materials from super hard materials such as diamond PCD and CBN ceramics.

The above mentioned processing procedure does not require mold opening or plate making, and it consumes very little materials and energy. It is currently a relatively ideal processing method for super hard materials.

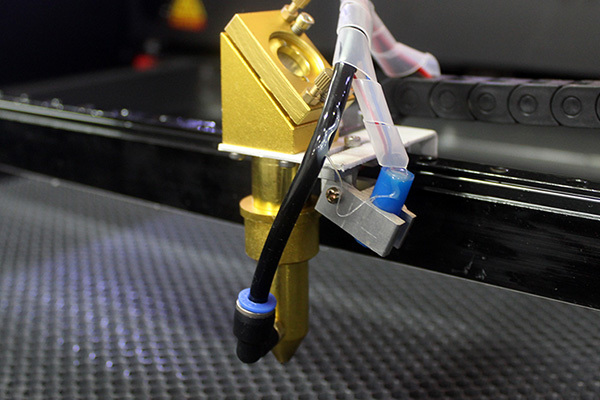

Super hard materials such as PCD/CBN/ceramics: according to the shapes of various cutting tools such as turning tools, moulding cutters, reamers, etc, to design a 2D graphics for cutting. When in laser cutting machine tool processing, the air from the nozzle at the same time, the material melting and carbon residue are blow out, accelerate the cutting speed and material temperature cooling, ensure the safety of personal and equipment, also can work our qualified beautiful parts.

Application scope of the product:

It can cut complex 2D geometric on metal materials such as PCD, PCNB, CNB ceramics, cemented carbide and mould steel, the cutting loss is small and the speed is high.

Recommended cutting materials: PCD, PCBN, CBN, ceramics, etc.

Product feature:

- It is controlled by computer and can cut out 2D geometric shapes through laser software.

- CCD vision display, high positioning accuracy and low error rate.

- The XY electric platform is used to place the material plate, with an electric Z-axis that can be operated manually or automatically.

- The marble platform ensure the overall seismic resistance of the equipment

- It is equipped with a vacuuming of the filtering device.

- The entire machine operates in a sealed space to ensure personal safety.

- The overall equipment has low consumption, requires few consumables and has low operating cost

Product parameter

Product power consumption: 4000W(peak) | Auxiliary: Air |

Workpiece positioning method: Manual positioning assisted by CCD camera | Laser processing range XYZ 200*200*100(customized) |

Product power supply:AC220V±10% 50HZ | Product vacuuming: involved(the filter bag is a consumable) |

Tray range(mm): Diameter 70-10 | Workpiece positioning accuracy:±0.015 |

Working temperature: 20℃ to 40 ℃ | Outline dimensions(mm) 1200*1000*1900 |

Cooling method: cooling | Workpiece positioning method: manual positioning assisted by CCD camera the above parameters are subject to the actual delivery. |

Laser type: nanosecond 150W(300W optional) |

Keywords

FAQ

What services can we provide?

We had provided numerous well-known companies with wide-ranging solutions and reliable equipment, with a sustainable and robust traceability to the industry.

Is customization supported?

Support customization, we have perfect quality and excellent after-sales service, escort for your needs

Our sales network

Our equipment are widely used and accepted all over the world, covering Europe, America, Mexico, Brazil, South Korea, India, Thailand, Vietnam, Malaysia, Singapore, and Indonesia, etc.

Super hard material laser cutting machine

Contact Us

Classification