ELF Science & Technology (Beijing) Co., Ltd

Add:2-2, Floor 1, Building 12, Changan Community, Miyun District, Beijing

Tel:+86 15010117905

Quote Now

Solutions for Your Industry, Ready for Your Choice

1 Overall

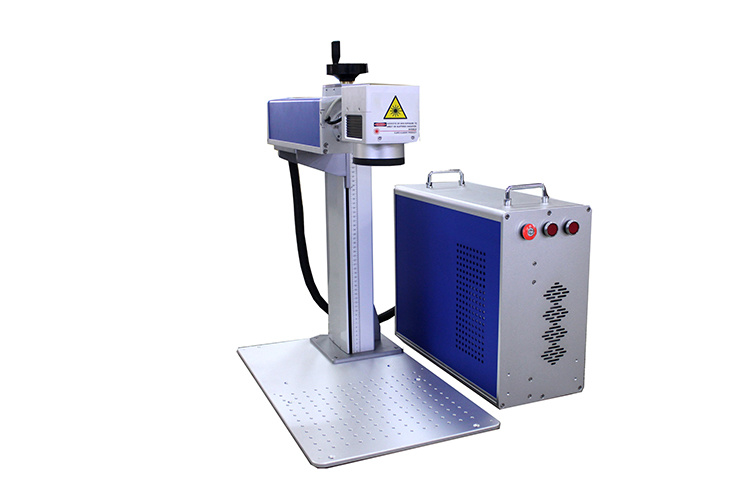

vertical milling machine is a machine tool with a wide range of applications. The machine tool has the characteristics of strong rigidity, wide feed speed change range and can bear heavy load chip. It can mill plane, inclined plane, groove, hole, spiral surface, milling cam and arc groove. It is an ideal processing equipment for machinery manufacturing, instruments, meters, molds, automobiles, motorcycles and other industries.

Product Description:

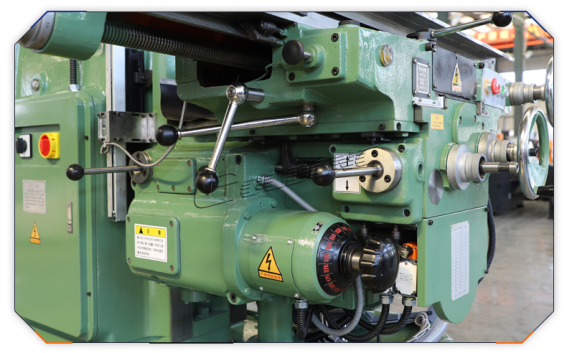

End milling head:

●The milling head can be adjusted forward and backward in the vertical plane by 45;.

●The spindle sleeve can be manually micro-feed, and is equipped with a limit device;

●The main shaft bearing adopts tapered roller bearing, which has strong carrying capacity and adopts energy consumption braking.

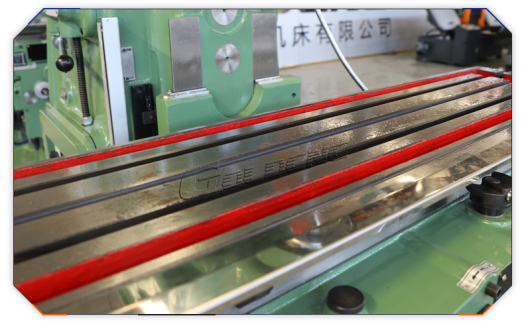

Workbench:

●The worktable and guide rail are audio-quenched, with high strength;

●Vertical and horizontal manual feeding and vertical lifting are possible, and at the same time, it can realize motorized fast forward, motorized feeding and vertical motorized lifting.

Lubrication device:

●Use forced lubrication;

●Forced lubrication of the X, Y, and Z-direction screws and guide rails reduces machine wear and ensures the efficient operation of the machine tool.

Table feed:

●There are three modes of manual feed, motorized feed, and motorized rapid feed in 3 directions of the worktable, which can meet different processing requirements;

●The rapid feed mode can make the workpiece quickly reach the processing position, shorten the non-processing time, and improve the work efficiency.

,Configurations

Main Configurations

No. | Name | Supplier |

1 | Bed casting | Own-brand(Resin sand) |

2 | Motor | Shandong Huali Group Shanghai Electric Machinery Factory |

3 | Electrical appliances | Zhengtai, Schneider |

4 | Gear | Shenyang Mechanical Group |

5 | Bearing | Haerbin Bearings |

Machine tool wearing parts and spare parts

(Customers prepare in advance according to actual needs)

Common spare parts:

No. | Name | Specifications |

1 | Milling cutter | Depends on your requirements |

2 | Wire and Cable | Depends on the distance between equipment placement and power supply |

3 | Coolant | Coolant:water =1:10 |

4 | Hydraulic oil | Depends on your requirements |

4.Attached Documents:

Technical Data

Instructions

Certificate of Conformity

Warranty Card

Packing List

5.Precautions for daily maintenance

In order to ensure the normal service life of the machine, please strictly follow the following maintenance items perform routine maintenance.

1. In order to ensure the mechanical accuracy, there must be regular and routine maintenance.

(1) After operation, all parts of the machine, especially the sliding parts, shall be wiped clean and oiled.

(2) Remove the milling chips from all parts.

(3) Rust proof shall be applied to necessary parts.

2. Precautions for daily use

(1) Before milling, please clamp the workpiece and tighten the tool;

(2) The proper milling cutter must be selected according to the material and hardness of the workpiece;

(3) Pay attention to the rotation direction of the spindle;

(4) During the milling process, it is forbidden to enter the working range of the milling cutter with hands (especially gloves).

3. Maintenance of lubrication system

The lubricating oil in the automatic oiler is consumable, please add it in time;

The grease nozzle of each part is marked with butter filling interval, please add butter in time.

6.Accessories

NO. | Name | Specification | Qty. | Note |

1 | Tie rod | | 1pc | |

2 | ISO50 milling chuck | 4、5、6、8、10、12、14、16 | 1 set | 8pcs/set |

3 | 7:24 Intermediate sleeve | 7:24 ISO50/MS4 | 1 set | |

4 | Shank type milling cutter arbor | ISO50-40 | 1 set |

|

5 | Piston oil gun | | 1 pc | |

6 | Anchor bolts | M20×500 | 4 sets | |

7 | Lifting handle |

|

| |

8 | Double-ended wrench | S17-19 | 1 pc | |

9 | Double-ended wrench | S22-24 | 1 pc | |

10 | Double-ended wrench | S27-30 | 1 pc | |

11 | Double-ended wrench | S32-36 | 1 pc | |

12 | Allen key | 5 | 1 pc | |

13 | Allen key | 6 | 1 pc | |

14 | Allen key | 8 | 1 pc | |

15 | Allen key | 10 | 1 pc | |

16 | Allen key | 160×80 | 4 sets | |

7.Technical Parameters

Specifications | X5032 | X5032B | X5032BH |

The distance from Spindle end to table(mm) | 60~410 | 60-410 | 60-500 |

The distance from the centerline of the spindle to the vertical guide rail of the bed (mm) | 350 | 350 | 350 |

Spindle taper | 7:24 ISO50 | 7:24 ISO50 | 7:24 ISO50 |

Spindle Bore hole(mm) | 29 | 29 | 29 |

Spindle speed(rpm) | 30-1500/18 step | 30-1500/18 step | 30-1500/18 step |

Vertical milling head max. Rotary (°) | ±45° | ±45° | ±45° |

Spindle travel(mm) | 85 | 85 | 85 |

Table size(mm) | 1325x320 | 1600x320 | 1600x320 |

Table travel (manual/maneuverable)(mm) | transverse:720/700 | transverse:900/880 | transverse:900/880 |

longitudinal:255/240 | longitudinal:255/240 | longitudinal:255/240 | |

vertical: 370/350 | vertical: 370/350 | vertical: 440/430 | |

Table feeding range(mm/min) | transverse:23.5~1180 | transverse:23.5~1180 | transverse:23.5~1180 |

longitudinal:23.5~1180 | longitudinal:23.5~1180 | longitudinal:23.5~1180 | |

vertical:8~394 | vertical:8~394 | vertical:8~394 | |

Table rapidly speed of moving(mm/min) | transverse:2300 | transverse:2300 | transverse:2300 |

longitudinal:2300 | longitudinal:2300 | longitudinal:2300 | |

vertical:770 | vertical:770 | vertical:770 | |

T-slot(mm) | 3/18/70 | 3/18/70 | 3/18/70 |

Main motor power(kw) | 7.5 | 7.5 | 7.5 |

Feeding motor power(kw) | 1.5 | 1.5 | 1.5 |

Machine size(mm) | 2530×1890×2380 | 2530×2050×2380 | 2530×2050×2380 |

Machine weight(kg) | 3200 | 3300 | 3400 |

Key Components

|

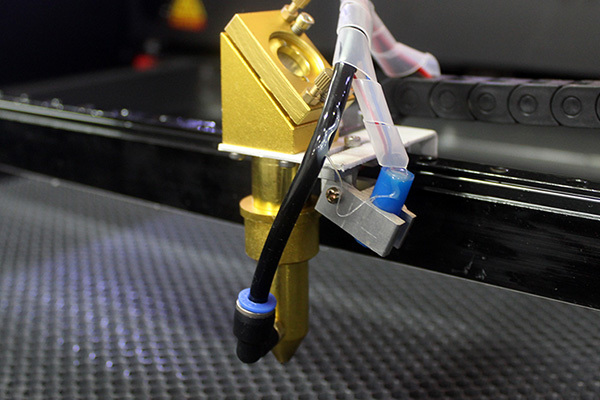

01-Machine head&Spindle The machine head can be rotated by ±45 degrees The gear speed of the machine head can be changed in 6 speeds,with strong power spindle motor. |

04-Automatic cutter X,Y, Z three-direction motorized feed. With hand wheel device, easy to operate |

|

|

03-Workbench X, Y, and Z direction guide rail sub-audio hardening and precision grinding |

Keywords

FAQ

What services can we provide?

We had provided numerous well-known companies with wide-ranging solutions and reliable equipment, with a sustainable and robust traceability to the industry.

Is customization supported?

Support customization, we have perfect quality and excellent after-sales service, escort for your needs

Our sales network

Our equipment are widely used and accepted all over the world, covering Europe, America, Mexico, Brazil, South Korea, India, Thailand, Vietnam, Malaysia, Singapore, and Indonesia, etc.

Vertical Milling Machine

Contact Us

Classification